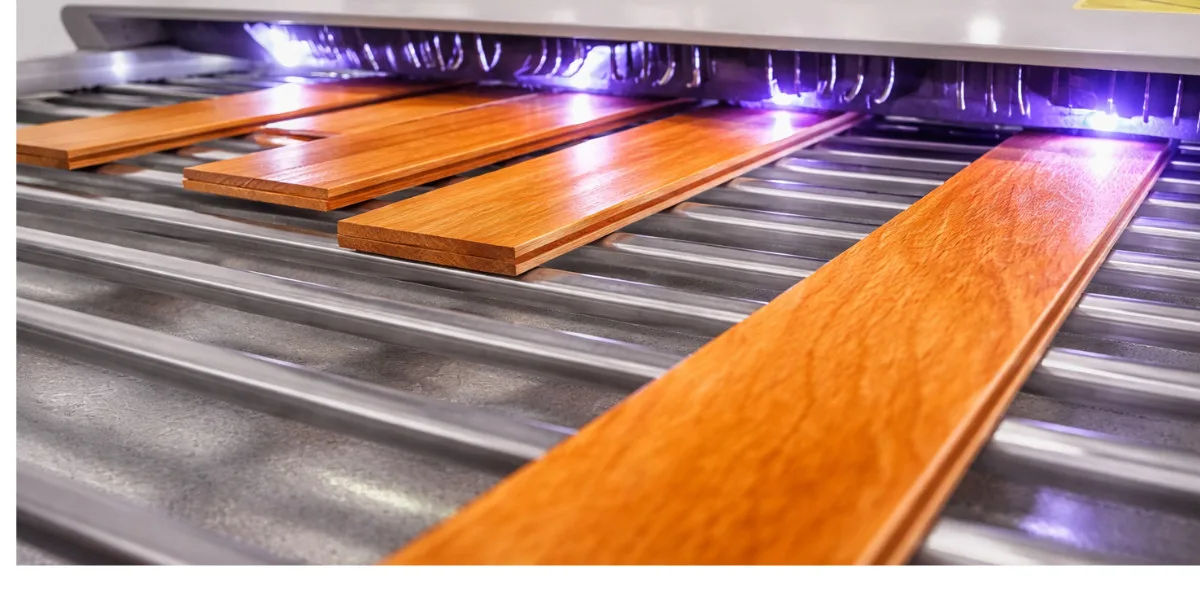

Discover how UV Curable Resin improves productivity and delivers superior surface finish in modern coating application

In today’s fast-paced manufacturing world, speed and quality matter. Every second counts. At the same time, surface finish defines product value. This is where UV Curable Resin changes the game.

Unlike conventional systems, UV Curable Resin hardens instantly under ultraviolet light. As a result, production lines move faster. Moreover, the final coating looks smoother and more refined. Therefore, many industries now prefer this advanced technology.

What Is UV Curable Resin?

UV Curable Resin is a light-activated polymer system. It remains liquid until exposed to UV light. Once exposed, it cures within seconds. The curing process is initiated by photo initiators. These compounds react when UV light is applied. Consequently, a strong cross-linked film is formed. The surface becomes hard, durable, and chemically resistant. Because of this fast reaction, downtime is reduced. In many cases, parts can be handled immediately after curing.

Advantages of UV Curable Resin

Faster Processing with UV Curable Resin

- Speed drives productivity. Traditional coatings often require heat or long drying cycles. However, UV Curable Resin cures almost instantly.

- First, the coating is applied. Next, it passes under a UV light. Within seconds, it becomes fully cured. Therefore, there is no waiting period.

- This instant curing increases line speed. In addition, it reduces storage space for drying racks. As a result, manufacturers can produce more in less time.

- Energy use is also lower. Ovens are not required in many systems. Thus, operational costs decrease. In high-volume industries such as wood coatings, electronics, and printing, productivity is significantly improved.

Superior Surface Finish

- While speed matters, finish defines product appeal. UV Curable Resin creates a smooth and uniform film. Because curing happens rapidly, dust contamination is minimized.

- Moreover, the coating levels well before curing. This ensures gloss consistency. In decorative applications, clarity and depth are enhanced.

- The surface is also harder. Therefore, scratch resistance improves. In addition, chemical resistance increases. Finished goods look premium and last longer.

- In furniture and flooring, this resin provides a rich, glossy appearance. In electronics, it delivers precision and protection. As a result, product quality is elevated.

Improved Mechanical Strength with UV Curable Resin

- Durability is essential. UV Curable Resin forms a dense cross-linked network. Consequently, the coating becomes tough and impact resistant. Thermal stability is improved. Moisture resistance is enhanced. In demanding environments, performance remains stable.

- Because of these properties, maintenance needs are reduced. Over time, lifecycle costs are lowered. This advantage is often overlooked, yet it adds strong value.

Environmental and Operational Benefits

- Sustainability is becoming a priority. Many UV Curable Resin systems are formulated with low or zero VOC content. Therefore, workplace emissions are minimized.

- Odor levels are low. Worker safety is improved. Additionally, compliance with environmental standards becomes easier.

- Material waste is also reduced. Since the resin cures on demand, unused material remains usable. Thus, efficiency increases across the production cycle.

Application Versatility of UV Curable Resin

Another strength of UV Curable Resin is its adaptability. It is used in:

- Wood and furniture coatings

- Industrial protective finishes

- Printing inks and overprint varnishes

- Electronic encapsulation

- Automotive refinishing

Each sector benefits differently. However, the core advantage remains the same: fast curing with superior finish.

Reduced Rework and Higher Output

- Rework slows production and increases cost. However, UV Curable Resin reduces surface defects. Because curing is controlled and immediate, inconsistencies are minimized.

- Parts are less likely to stick together. Blocking is prevented. Furthermore, uniform hardness is achieved across the surface.

- As a result, rejection rates decrease. Productivity rises. Output becomes more predictable. These improvements are measurable and consistent.

Why Industries Prefer UV Curable Resin?

Manufacturers look for reliability. They want speed, strength, and surface perfection. UV Curable Resin delivers all three.

It simplifies processes. It shortens cycle time. It enhances product aesthetics. At the same time, environmental impact is reduced.

Although initial equipment investment may be required, long-term gains are substantial. Production efficiency is improved. Product value is increased. Customer satisfaction is strengthened.

Concluding Thoughts

UV Curable Resin has transformed modern coating technology. It offers instant curing, higher throughput, and outstanding finish quality. Moreover, it supports sustainable manufacturing practices.

Because productivity and surface excellence are both enhanced, industries continue to adopt this technology. In competitive markets, this advantage matters. Ultimately, UV Curable Resin does not just improve coatings. It improves the entire production process.

COMPANY INFO

Website: www.crestresins.com

Phone: +91 9879233188

Email: enquiry@crestresins.com

Address: 605/A, 6th Floor, Tower D, Times Square Grand Office, Sindhubhavan Marg, Near Taj Hotel, Ahmedabad, Gujarat - 380059