Discover how Dough Moulding Compound (DMC) resin enables high-volume manufacturing of electrical enclosures and housing appliances with durability, precision, and cost-efficiency.

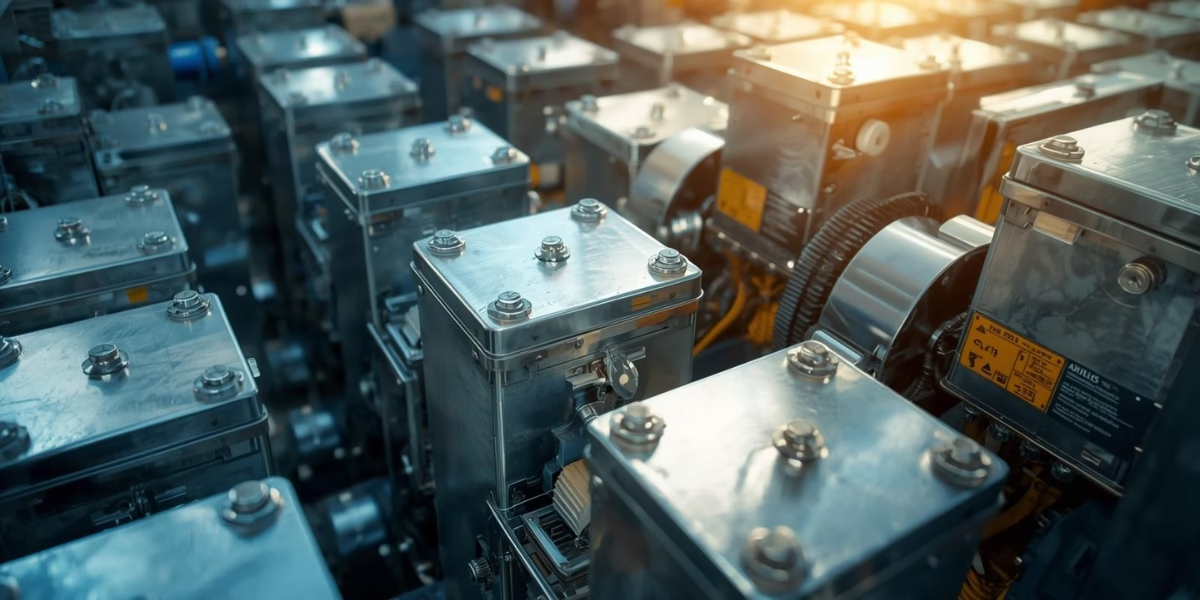

In today’s manufacturing environment, speed, quality, and cost matter. For enclosures in the electrical and appliance sectors, materials must deliver on all three. The Dough Moulding Compound (DMC) resin rises to the challenge. In this blog, we explore how DMC resin powers high-volume production of electrical enclosures and appliance housings, why it is chosen, and what benefits it brings.

What Is DMC Resin in This Context?

DMC resin is a ready-to-mould fibre-reinforced thermosetting composite. Once moulded under heat and pressure, the material cures into a rigid, durable component that cannot be remelted. This makes it ideal for high-volume production of parts requiring mechanical strength, electrical insulation, and dimensional stability.

Why Manufacturers Choose DMC for Enclosures and Appliances?

In the manufacture of electrical enclosures (switchgear boxes, junction boxes) and housing appliances (washing machines, microwaves, etc.), DMC offers a unique combination of attributes:

Electrical Insulation and Flame Resistance of DMC

DMC is widely used for electrical switchgear housings and insulating components because it meets the needed safety standards.

Dimensional Accuracy and Stability

For housings that must fit tightly with other components, DMC offers low shrinkage and consistent performance.

Corrosion and Chemical Resistance

Outdoor or appliance parts face moisture, temperature swings and DMC stands up well.

High-Volume Cost-Effectiveness

Because DMC can be moulded rapidly (especially via compression moulding) and produces parts with good surface finish and mechanical properties, it becomes economical in large runs.

DMC Offers Material Versatility

Different formulations of DMC allow adjustment in fibre content, fillers, fire-retardant additives, and surface finish for specific enclosure/housing needs.

How DMC Works in High-Volume Manufacturing?

To capitalise on its advantages, manufacturers set up production lines that align with DMC’s processing strengths:

Cycle Time Optimisation

Because high-volume production demands fast turnaround, DMC allows relatively short curing times compared to some other composites, while achieving dimensional control and strength.

Minimal Finishing with DMC

DMC parts often come out of the mould with good surface quality and require limited post-machining or trimming. This reduces labour and costs.

Integration of Features

Inserts (metal bosses, threaded inserts), embedded components or ribs can be moulded directly, supporting complex part design common in enclosures and housings.

Key Benefits in High-Volume Production

When implemented properly, DMC resin brings manufacturers notable advantages:

Scale Efficiency with DMC

Moulding large batches becomes more predictable and cost-effective because DMC reduces scrap and ensures repeatable quality.

Fewer Material Substitutions

With DMC, one material system handles insulation, strength, finish, and supply chain and tooling is simplified.

Lower Maintenance and Replacements

Enclosures and housing appliances made from DMC resist warpage, corrosion and ageing; this reduces warranty costs.

Design Freedom

Manufacturers can design appliances with complex shapes, integrated ribs, and inserts, without resorting to multiple parts or costly assemblies.

Sustainability Potential

While thermosets are traditionally harder to recycle, longer product life and substitution of heavier metals help in sustainability.

Considerations for Best Results

To fully leverage DMC resin in high-volume manufacturing, consider these factors:

Material Selection: Choose DMC grades optimised for the specific application such as fire-retardant grades for electrical enclosures, UV-stable grades for outdoor housings.

Cycle Time Balancing: While DMC offers speed, manufacturers must balance cure time, pressure, and cooling to maximise throughput without compromising quality.

Insert and Assembly Integration: Pre-placing inserts or designing for mating with other components should be planned at the design phase.

Quality Control: Because high-volume implies tight tolerances and minimal defects, monitoring dimensional stability, surface finish, and mechanical/electrical properties is essential.

Final Thoughts

Dough Moulding Compound or DMC resin is a pivotal material for manufacturing electrical enclosures and appliance housings at scale. Its thermosetting nature, excellent electrical insulation, mechanical strength, and ability to deliver precise, moulded parts make it ideal for high-volume runs. When coupled with efficient moulding processes and purpose-built tooling, DMC allows manufacturers to hit cost, quality and time targets simultaneously.

COMPANY INFO

Website: www.crestresins.com

Phone: +91 9879233188

Email: enquiry@crestresins.com

Address: 605/A, 6th Floor, Tower D, Times Square Grand Office, Sindhubhavan Marg, Near Taj Hotel, Ahmedabad, Gujarat - 380059