Discover how acrylic resins enhance protective coatings for industrial machinery and metalwork, delivering superior corrosion resistance, gloss stability, and durability in harsh environments.

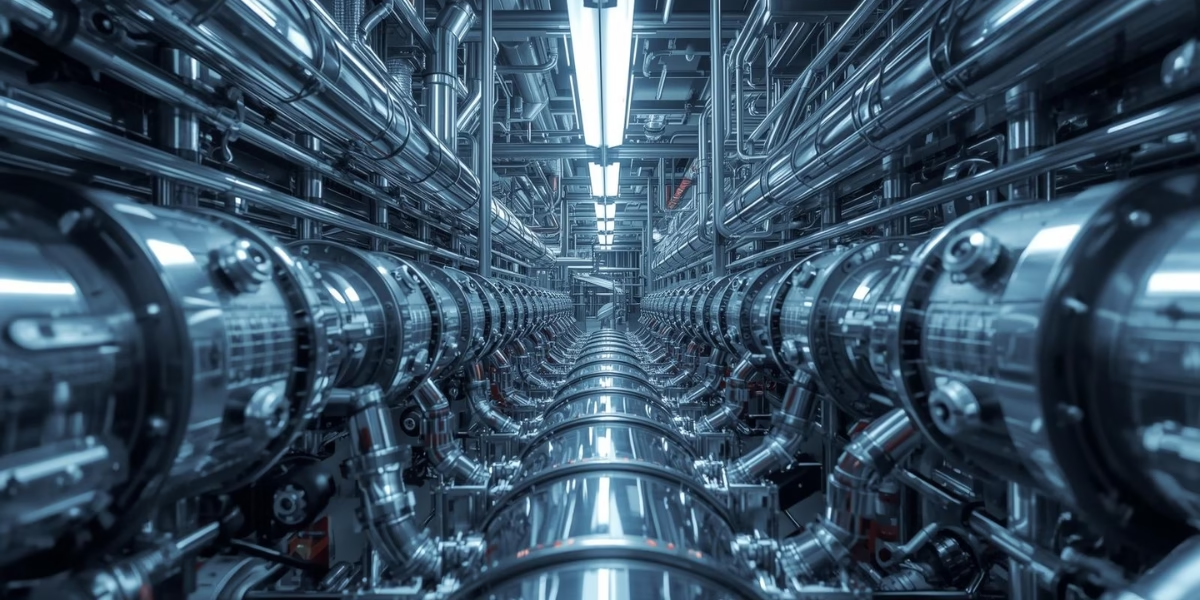

Industrial equipment and metal components are exposed to tough conditions like heat, moisture, chemicals, and constant wear. Without proper protection, these factors can cause corrosion and surface degradation, reducing operational life. Acrylic resin-based coatings have become a trusted choice to safeguard such assets. Their unique balance of flexibility, durability, and weatherability makes them ideal for demanding industrial environments.

What Makes Acrylic Resins Ideal for Industrial Coatings?

Acrylic resins are polymers derived from acrylic and methacrylic acids. They are widely used as binders in protective coatings due to their clarity, UV stability, and adhesion to metal surfaces. When applied to machinery and structural metalwork, acrylic coatings form a tough, continuous film that shields against environmental and mechanical stress.

How Acrylic Resins Work?

Shielding Against Moisture and Chemicals

Industrial plants and workshops often contain moisture, oil mist, and chemical vapors. Acrylic coatings act as a strong barrier layer, preventing water and corrosive agents from reaching the metal surface. Their tight polymer structure enhances resistance to hydrolysis and oxidation.

Compatibility with Primers and Topcoats

Acrylic resins can be used as single-component coatings or combined with epoxy primers for enhanced protection. In heavy-duty machinery, this hybrid approach provides a multi-layer shield that resists both chemical attack and abrasion.

Performance in Aggressive Environments

From power plants to refineries, machinery faces continuous exposure to heat, solvents, and humidity. Acrylic coatings maintain firm integrity, even when subjected to temperature cycles or vibration. Their ability to resist cracking and peeling ensures long-term protection.

Acrylic Resins Provide Stability Under the Sun

Acrylic Resins Help to Retain the Gloss and Colour

Acrylic resins are naturally resistant to UV radiation. They protect both the coating film and the pigments within, preventing chalking and fading. This property is crucial for outdoor machinery, cranes, and transport vehicles. Even after years of exposure, surfaces coated with acrylic retain their brightness and smoothness.

Surface Durability in Changing Conditions

Industrial environments see drastic shifts from high heat near furnaces to cold storage areas. Acrylic coatings adapt to these conditions without losing flexibility or adhesion. Their sustainability ensures that coated parts maintain an attractive, professional appearance over time.

Quick Drying and Application

Downtime in industrial facilities is costly. Acrylic coatings cure quickly at ambient or low-bake temperatures, allowing faster return to service. This fast-cure property makes them ideal for production lines or maintenance schedules where speed matters.

Easy Repair and Overcoating

In case of wear or damage, acrylic coatings can be easily sanded and recoated without compatibility issues. Their excellent adhesion simplifies touch-ups and periodic maintenance.

Low Maintenance & High Payoff

Because acrylics resist dirt and staining, machinery remains cleaner for longer. This reduces cleaning frequency and maintenance costs as an advantage for facilities operating under harsh, dusty, or chemical-heavy conditions.

Acrylic Resins Application Areas Across Industries

Acrylic-based protective coatings are used in:

- Industrial machinery (pumps, compressors, turbines)

- Metal fabrication (tanks, frames, tools)

- Automotive and transport equipment

- Agricultural and construction machinery

- Outdoor installations (fences, pipelines, power housings)

Their versatility makes them suitable for both new equipment protection and maintenance coating systems.

Concluding Thoughts

Acrylic resins deliver a winning combination of UV stability, fast curing, and surface protection, making them one of the most reliable materials for protective coatings in industrial and metalworking environments.

Their ability to stand up to moisture, chemicals, and sunlight ensures long-lasting performance and keeps machinery efficient and surfaces looking new. For industries seeking dependable protection with lower maintenance demands, acrylic resin coatings offer a cost-effective, high-performance solution.

COMPANY INFO

Website: www.crestresins.com

Phone: +91 9879233188

Email: enquiry@crestresins.com

Address: 605/A, 6th Floor, Tower D, Times Square Grand Office, Sindhubhavan Marg, Near Taj Hotel, Ahmedabad, Gujarat - 380059