Learn how Fire-Retardant Resins enhance safety in electrical enclosures by offering heat resistance, insulation, and long-term protection against electrical fires and system failures.

Electrical systems are the backbone of modern infrastructure. However, they also carry significant fire risks due to heat buildup, short circuits, and electrical faults. Because of this, industries are increasingly adopting composite materials made with Fire-Retardant Resins. These resins improve safety, enhance insulation, and provide long-term reliability in demanding conditions.

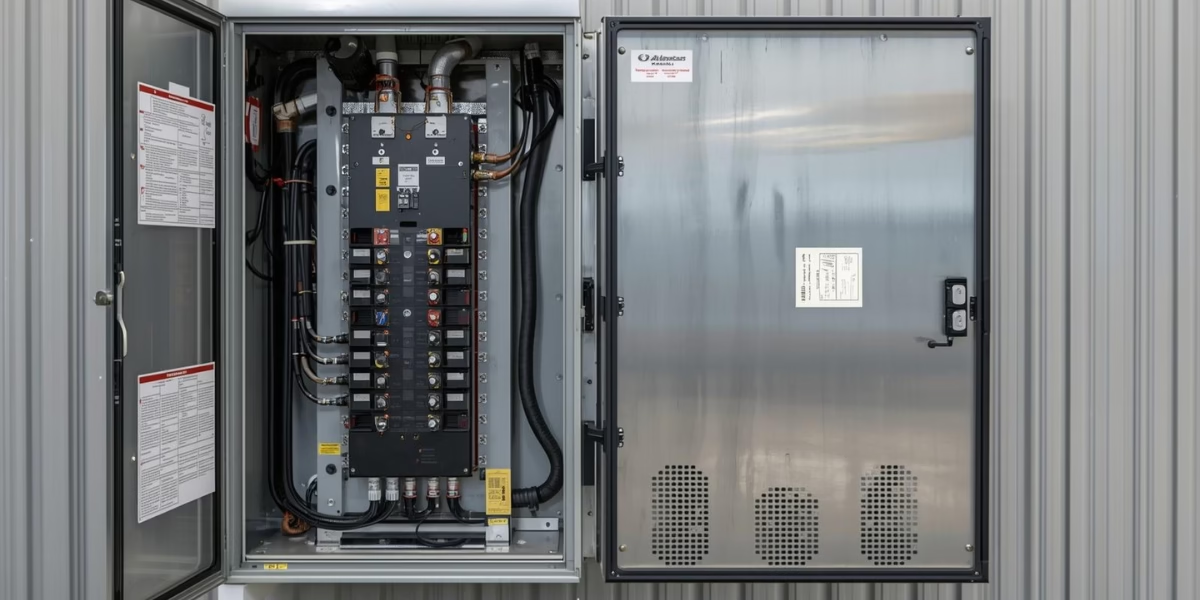

Electrical enclosures must perform under high voltage and harsh environments. Therefore, materials used in their construction must resist ignition, limit flame spread and maintain structural integrity during exposure to heat. Fire retardant resin systems meet these exact needs, making them essential in electrical safety engineering.

What Are Fire Retardant Resins?

Fire retardant resins are specially formulated polymer systems designed to slow down or prevent the spread of fire. They contain additives or reactive chemicals that reduce flammability, release minimal smoke, and maintain strength under heat.

When used in electrical enclosures, these resins provide multifunctional protection. They improve thermal stability. They also enhance mechanical strength and resist chemical exposure to some extent. As a result, they support safer and longer-lasting electrical systems.

Why Electrical Enclosures Need Fire Protection?

Electrical equipment generates heat during operation. Overloads, cable faults, and component failures can increase this heat, sometimes leading to ignition. Additionally, enclosures often house sensitive electronics. Any fire can cause severe damage, downtime, and safety hazards.

Therefore, manufacturers must choose materials that can:

- Withstand high temperatures

- Prevent fire spread

- Protect internal components

- Maintain insulation properties

- Resist corrosion and mechanical stress

Fire Retardant Resins provide all these benefits, making them one of the most reliable materials for electrical safety.

Key Benefits of Fire-Retardant Resins in Electrical Enclosures

Fire-Retardant Resins High Thermal Resistance and Flame Protection

Electrical enclosures must resist high temperatures. Fire retardant resins form a protective char layer when exposed to heat. This layer insulates internal components and slows down the burning process.

Consequently, the enclosure maintains structural strength longer, giving systems more time to shut down safely.

Fire Retardant Resins Offer Reduced Smoke and Toxic Emissions

During a fire, smoke and toxic gases create major hazards. However, many fire-retardant resins are designed to release minimal smoke. They also reduce harmful emissions. Additionally, they help improve visibility during evacuation and lower risk for maintenance personnel. This makes them ideal for enclosed environments such as control rooms or substations.

Corrosion and Chemical Resistance

Electrical equipment often operates in industrial environments exposed to moisture, chemicals, or dust. Fire retardant composite enclosures resist corrosion far better than metal alternatives. Therefore, they are suitable for coastal regions, chemical plants, and outdoor installations.

Applications of Fire-Retardant Resins in Electrical Systems

Low-Voltage and Medium-Voltage Enclosures

Electrical enclosures require high fire safety. Resin-based components offer flame resistance while keeping the unit lightweight and easy to install.

Control Panels and Distribution Boxes

These panels house delicate circuits. Fire retardant resin enclosures protect equipment from external fire sources and internal overheating.

Transformer and Battery Storage Compartments

Resin composites help contain thermal events. They slow fire propagation in high-energy electrical systems.

How Fire-Retardant Resins Improve System Reliability?

The reliability of electrical systems depends heavily on the stability of enclosure materials. Fire Retardant Resins offer:

- Resistance to thermal cycling

- Long-term weatherability

- Lower maintenance requirements

- Consistent performance in extreme conditions

Because of these qualities, they reduce downtime and improve overall system safety.

Sustainability and Future Trends

The industry is shifting toward more sustainable materials. As a result, resin manufacturers are developing halogen-free fire retardant systems. These resins reduce environmental impact without compromising performance.

Concluding Thoughts

Fire Retardant Resins play a vital role in enhancing safety for electrical enclosures. They offer exceptional heat resistance, insulation, and structural durability. More importantly, they help reduce fire risks, protect components, and support long-term reliability in critical electrical systems.

As the demand for safer electrical infrastructure grows, fire retardant resin technology will continue to evolve, shaping a more secure and efficient future for industrial and commercial applications.

COMPANY INFO

Website: www.crestresins.com

Phone: +91 9879233188

Email: enquiry@crestresins.com

Address: 605/A, 6th Floor, Tower D, Times Square Grand Office, Sindhubhavan Marg, Near Taj Hotel, Ahmedabad, Gujarat - 380059