Unsaturated Polyester Resin plays a major role in modern manufacturing. It is widely used across industries. From lightweight composites to strong industry specific materials, this resin delivers consistent value. Moreover, it balances performance and cost effectively.

Because of its versatility, Unsaturated Polyester Resin continues to grow in demand. It supports innovation. At the same time, it ensures durability. Let us explore how this resin works across composites, construction, and coatings.

What Is Unsaturated Polyester Resin?

Unsaturated Polyester Resin is a thermosetting polymer. After curing, it forms a rigid and durable structure. Because of its chemistry, the resin offers good mechanical strength and chemical resistance. Most importantly, it is easy to process. Therefore, it suits both small-scale and industrial applications.

Unsaturated Polyester Resin in Composites

Composites are one of the largest markets for Unsaturated Polyester Resin. It is commonly reinforced with glass fibers. This combination creates strong yet lightweight materials.

For example, it is used in:

- Boat hulls

- Automotive panels

- Storage tanks

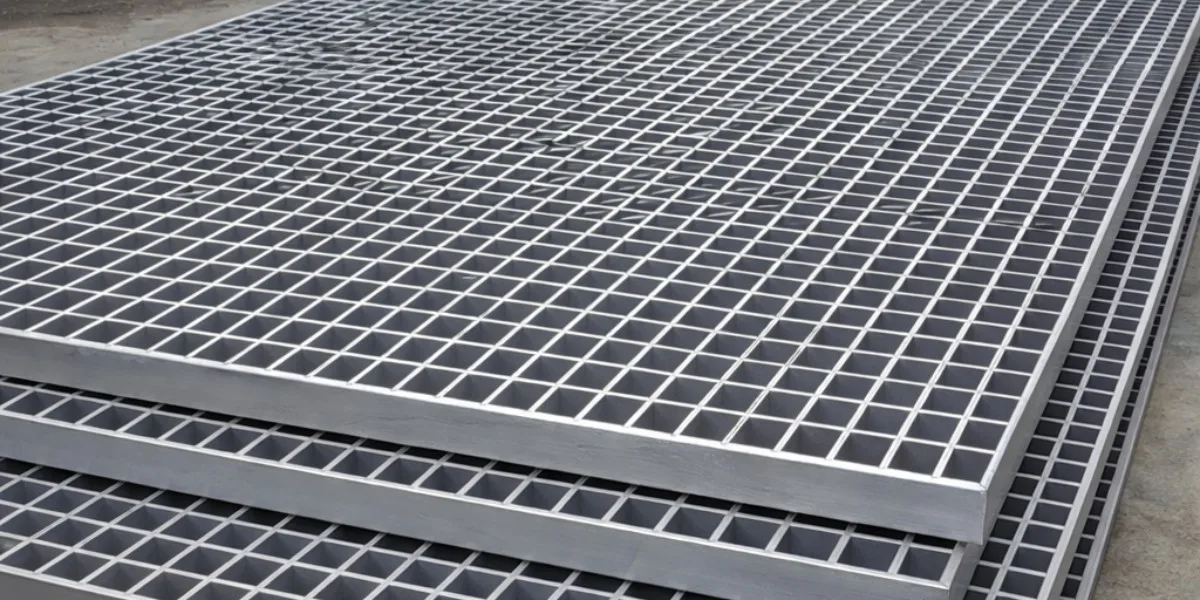

- Pipes and gratings

The resin binds fibers efficiently. As a result, structural strength is improved. Additionally, production costs remain low. Although epoxy resins are sometimes preferred, Unsaturated Polyester Resin is often chosen for high-volume production. This is because faster curing is achieved. Also, moulds can be reused easily.

UPR in Coatings

In coatings, Unsaturated Polyester Resin delivers excellent surface finish. It is widely used in gelcoats and industrial coatings.

These coatings offer:

- Smooth appearance

- Chemical resistance

- UV stability

- Abrasion resistance

As a result, coated surfaces last longer. Marine and industrial environments benefit the most. Moreover, the resin allows pigmentation easily. Therefore, color consistency is maintained. This makes it ideal for decorative and functional coatings.

Key Advantages of Unsaturated Polyester Resin

Several advantages make Unsaturated Polyester Resin a preferred choice:

- Easy processing

- Cost efficiency

- Good mechanical strength

- Compatibility with reinforcements

- Fast curing time

Additionally, it can be modified. Performance can be tailored. Hence, it fits diverse industry needs. While other resins exist, few offer such balance between price and performance.

Sustainability and Future Outlook

Sustainability is gaining importance. Fortunately, Unsaturated Polyester Resin is evolving. Bio-based raw materials are now being explored. Emissions are being reduced.

Also, recycling methods for composites are improving. Because of this, environmental impact is being addressed gradually. In the future, demand will continue to rise. Infrastructure growth and lightweight materials will drive usage further.

Concluding Thoughts

Unsaturated Polyester Resin remains a backbone material across composites and coatings. It delivers strength. It offers flexibility. Most importantly, it stays economical.

Because of its proven performance, industries continue to rely on it. As innovation advances, this resin will remain relevant for years to come. If you are looking for a reliable material solution, Unsaturated Polyester Resin is worth considering.

COMPANY INFO

Website: www.crestresins.com

Phone: +91 9879233188

Email: enquiry@crestresins.com

Address: 605/A, 6th Floor, Tower D, Times Square Grand Office, Sindhubhavan Marg, Near Taj Hotel, Ahmedabad, Gujarat - 380059