Electrical goods have become an essential part of both home and office spaces. Every switch, socket, or appliance must be safe, reliable, and long-lasting. Therefore, materials used in electrical manufacturing play a critical role in performance. One such material that often goes unnoticed, but delivers exceptional results, is DMC resin.

DMC resin, or Dough Moulding Compound, is a ready-to-mould thermoset compound known for its strength, insulation capability, and design flexibility. As modern homes demand safer and more stylish electrical products, DMC resin is becoming a key choice for manufacturers worldwide. Although you may not notice it, this versatile resin is present in many everyday electrical components. In this blog, we explore how DMC resin boosts safety, durability, and usability across a wide range of electrical goods.

What Makes DMC Resin Unique?

Because of this strong combination, components made using DMC resin offer:

- Excellent electrical insulation

- High mechanical strength

- Strong heat and flame resistance

- Stable dimensional accuracy

- Resistance to moisture and chemicals

These qualities make DMC resin ideal for products that must remain safe while working under electrical load.

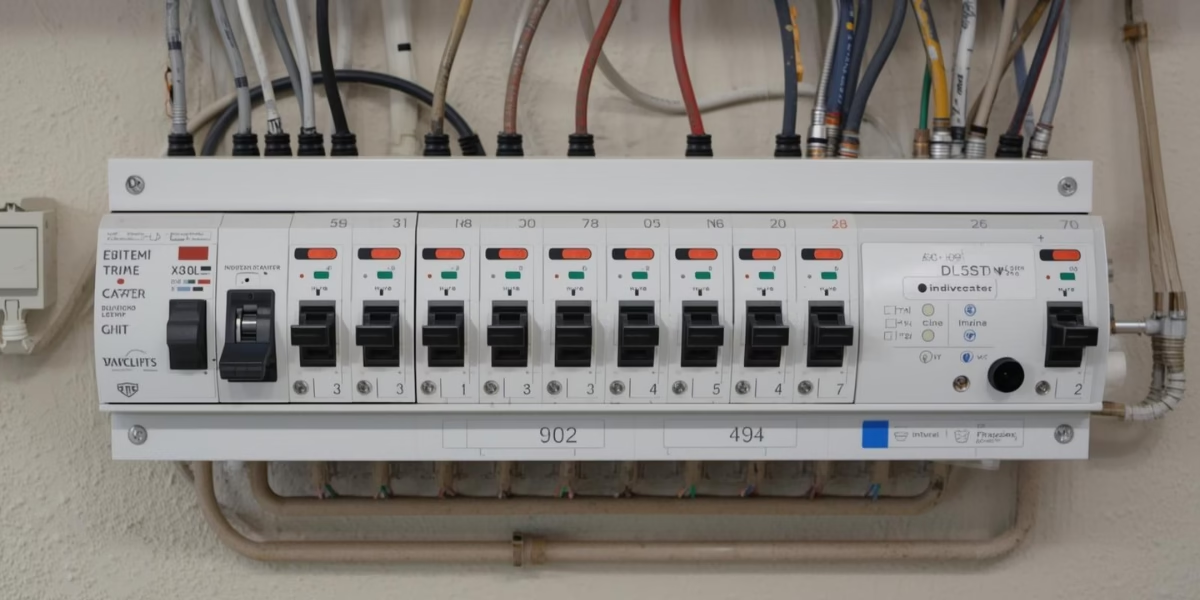

DMC Resin in Household Switchboards

Switchboards are one of the most common places where DMC resin is used. They must handle heat, electrical stress, and daily wear. Moreover, they need to look neat in modern interiors.

Superior Electrical Insulation

Switchboards require materials that block electric leakage. With its high dielectric strength, DMC resin provides safe insulation for both household and industrial use. As a result, the risk of short circuits is significantly reduced.

High Heat Resistance

Switchboards often handle high loads from large appliances. DMC resin keeps the structure stable even at elevated temperatures. Because of this, switchboards last longer and perform reliably.

Smooth and Clean Appearance

Switchboards need a clean, modern look. DMC resin allows for a smooth finish and consistent colouring. In many cases, it can be moulded into sleek designs that enhance interior décor.

DMC Resin in Sockets and Electrical Covers

Sockets, plugs, and cover plates are used constantly. They need to withstand repeated plugging and unplugging while remaining safe.

Impact and Scratch Resistance

DMC resin is tough. It resists cracks and dents even with heavy use, which means sockets look newer for longer.

Moisture Resistance

In homes, sockets are exposed to moisture and dust. Because DMC resin resists water and humidity, it prevents damage and enhances user safety.

Long-Term Colour Stability

Unlike many plastics that fade, DMC resin keeps its colour for years, even under sunlight. This makes it ideal for decorative switch plates and cover frames.

Usage in Small Home Appliances

While people often associate DMC resin with electrical components, it is also used widely in small appliances. Its appearance, strength, and heat resistance make it perfect for both interiors and outer casings.

Heat-Tolerant Interiors

Parts of appliances like irons, mixers, toasters, and hair dryers must tolerate heat. DMC resin does not deform easily and holds its shape, even when exposed to rising temperatures.

Enhanced Mechanical Strength

Moving and load-bearing parts benefit from DMC resin. It adds strength without increasing weight, which helps appliances become more durable and user-friendly.

Design Flexibility

Manufacturers can mould DMC resin into complex shapes. As a result, appliances become more ergonomic, visually appealing, and easier to handle.

DMC Resin in Office Electrical Goods

In office spaces, electrical equipment needs to be both strong and professional-looking. DMC resin supports these needs effectively.

Reliable Performance for High Usage

Office electrical points are used throughout the day. DMC resin ensures that high-traffic components like modular switches and junction boxes remain stable and safe under repeated use.

Why DMC Is Becoming A Preferred Choice?

The rise in demand for safer and smarter electrical goods has encouraged manufacturers to shift toward thermoset materials. DMC resin stands out because it combines strength, thermal stability, and safety. Additionally, it supports modern designs with smooth textures and consistent colours.

As sustainability also becomes a priority, DMC resin offers longer product life and reduces material failures. Because of these advantages, it is now commonly found in:

- Switchboards

- Sockets and adaptors

- MCB and MCCB components

- Motor housings

- Appliance parts

- Junction boxes

- Decorative switch plates

Many of these items are used daily, yet most people never realize how much of their safety depends on the material inside.

Concluding Thoughts

From your living room switchboard to your office socket panel, DMC resin plays a quiet but crucial role. Its insulation strength, mechanical durability, and design-friendly nature make it a smart choice for electrical goods. As homes and workplaces evolve, the need for reliable, heat-resistant, and attractive electrical components will continue to grow. DMC resin stands ready to meet these expectations and shape the future of modern electrical design.

COMPANY INFO

Website: www.crestresins.com

Phone: +91 9879233188

Email: enquiry@crestresins.com

Address: 605/A, 6th Floor, Tower D, Times Square Grand Office, Sindhubhavan Marg, Near Taj Hotel, Ahmedabad, Gujarat - 380059