Industrial coatings do more than protect surfaces—they define aesthetics and durability. In sectors like automotive, marine, and construction, vibrant colors and long-lasting finishes are non-negotiable. Enter customizable pigmented gelcoats for vibrant industrial coatings, a game-changing solution blending creativity with resilience. These advanced coatings allow precise color matching, withstand harsh conditions, and offer unmatched versatility. Let’s explore why they’re reshaping the industry.

Why Customizable Pigmented Gelcoats Are Essential for Vibrant Industrial Coatings

Traditional coatings often fail to balance color brilliance with durability. Standard options fade, crack, or peel under UV exposure or chemical stress. Customizable pigmented gelcoats solve this. They combine high-grade pigments with robust resin systems, creating coatings that stay vibrant for years.

Industries now prioritize branding through color. Construction equipment, marine vessels, and automotive parts demand unique hues for identity. Customizable gelcoats deliver exact shades, ensuring brand consistency. Additionally, their chemical resistance reduces maintenance costs. This dual benefit of aesthetics and performance makes them indispensable.

Key Benefits of Customizable Pigmented Gelcoats in Industrial Applications

1. Precision Color Matching: Achieve any shade for branding or design needs.

2. UV and Chemical Resistance: Retain vibrancy despite sun, salt, or solvents.

3. Enhanced Durability: Resist chipping, abrasion, and corrosion.

4. Eco-Friendly Formulas: Many gelcoats now use low-VOC materials.

For instance, marine manufacturers use these gelcoats to keep boats colorful in salty environments. Similarly, automotive companies apply them to machinery exposed to oils and fuels.

Innovations in Customizable Pigmented Gelcoat Technology

Recent advancements focus on sustainability and smart functionality. Bio-based resins and recycled pigments reduce environmental impact. Meanwhile, “smart” gelcoats with self-healing properties repair minor scratches automatically.

Nanotechnology also plays a role. Nano-pigments improve color density, requiring less material for coverage. Spray-applied gelcoats now dry faster, cutting production time. These innovations make customizable options more efficient and accessible.

How to Choose the Right Customizable Pigmented Gelcoat

First, assess the substrate—metal, fiberglass, or concrete. Next, consider environmental exposure. For outdoor use, prioritize UV-resistant formulas. Indoor applications might focus on chemical resistance.

Work with suppliers offering color-matching services. Test small batches before full-scale use. Finally, balance cost with quality. Premium gelcoats may cost more upfront but save money through longevity.

The Future of Vibrant Industrial Coatings: Customizable Gelcoats Lead the Way

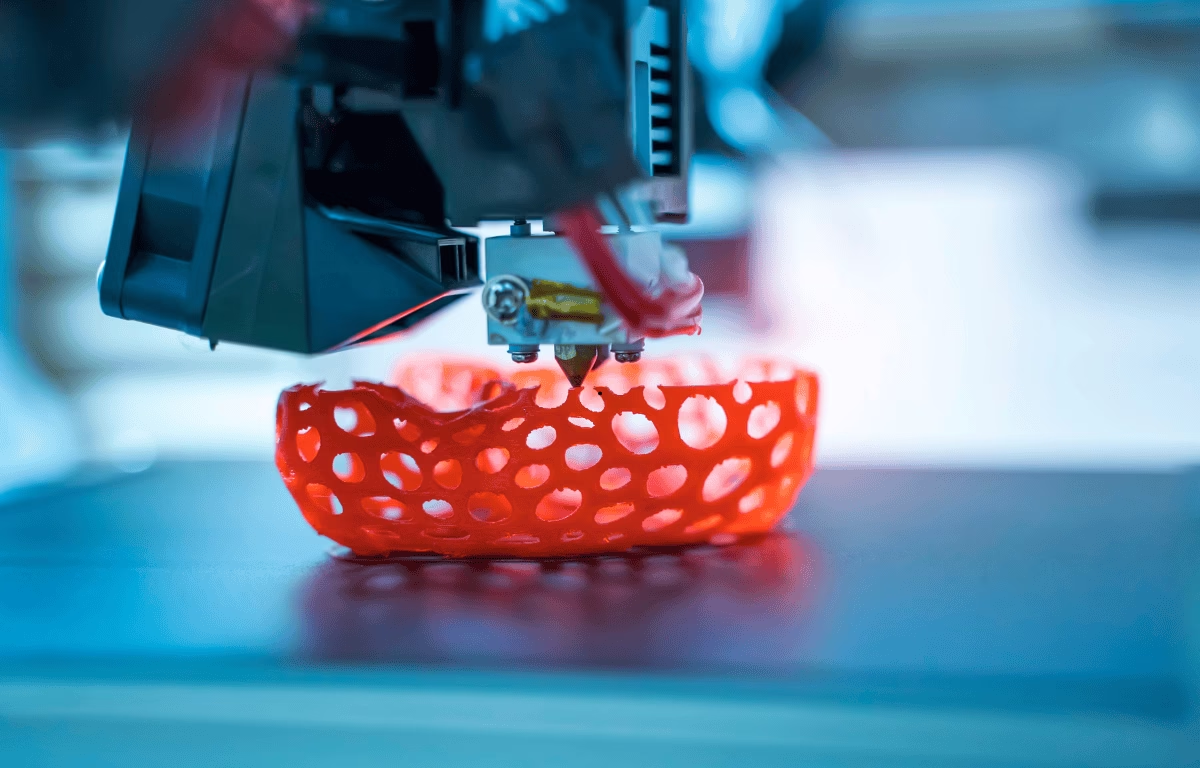

Demand for eco-friendly and durable coatings will grow. Customizable pigmented gelcoats will dominate, driven by 3D-printing compatibility and IoT integration. Imagine coatings that change color via app or signal wear-and-tear!

Regulations pushing greener solutions will also boost adoption. Companies using these gelcoats will attract eco-conscious clients and comply with laws effortlessly.

Conclusion

Customizable pigmented gelcoats for vibrant industrial coatings are transforming how industries approach aesthetics and durability. They offer unmatched color precision, resilience, and sustainability. As technology advances, their applications will expand, making them a staple in modern manufacturing.

Embrace this innovation to stay competitive and meet evolving consumer demands. The future of industrial coatings isn’t just bright—it’s vividly customizable.

COMPANY INFO

Website: www.crestresins.com

Phone: +91 9879233188

Email: enquiry@crestresins.com

Address: 605/A, 6th Floor, Tower D, Times Square Grand Office, Sindhubhavan Marg, Near Taj Hotel, Ahmedabad, Gujarat - 380059