Discover how Coil Coating Resin powers durable, corrosion-resistant finishes for construction and infrastructure, improving lifespan, aesthetics, and performance.

Author Archives: CREST

Discover why Unsaturated Polyester Resin dominates composite manufacturing, offering cost efficiency, strength, versatility, and scalable production across industries.

Discover how High Temperature Silicone Epoxy Resin provides thermal stability, durability, and reliable protection for demanding industrial environments.

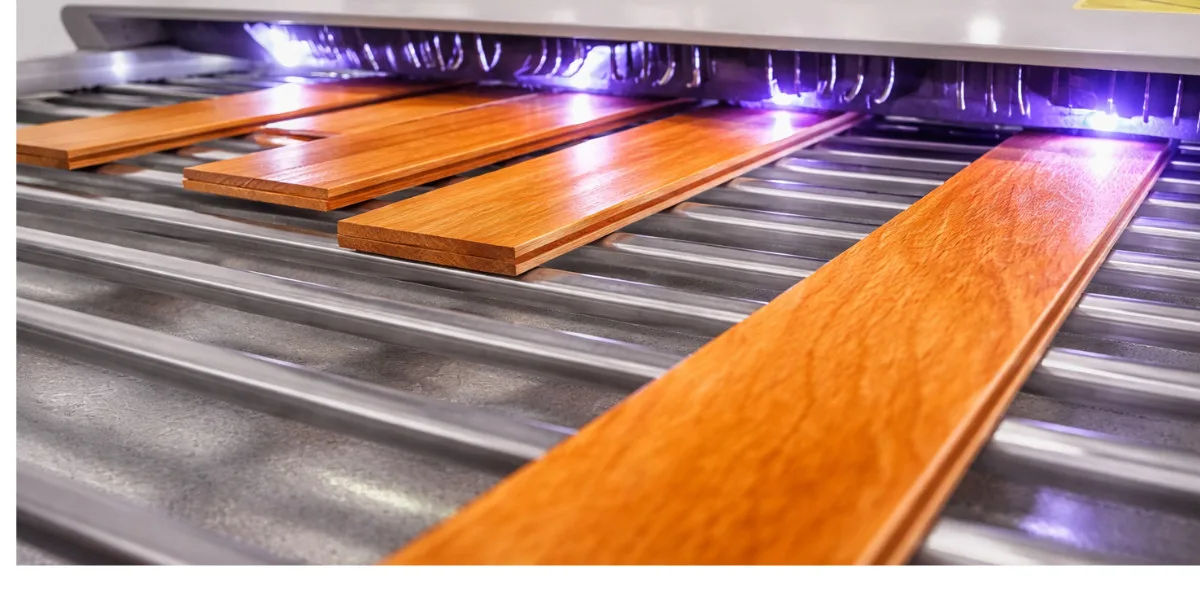

Discover how wood coating resin enhances durability, appearance, and long-term protection. Learn the key performance benefits for modern wood applications.

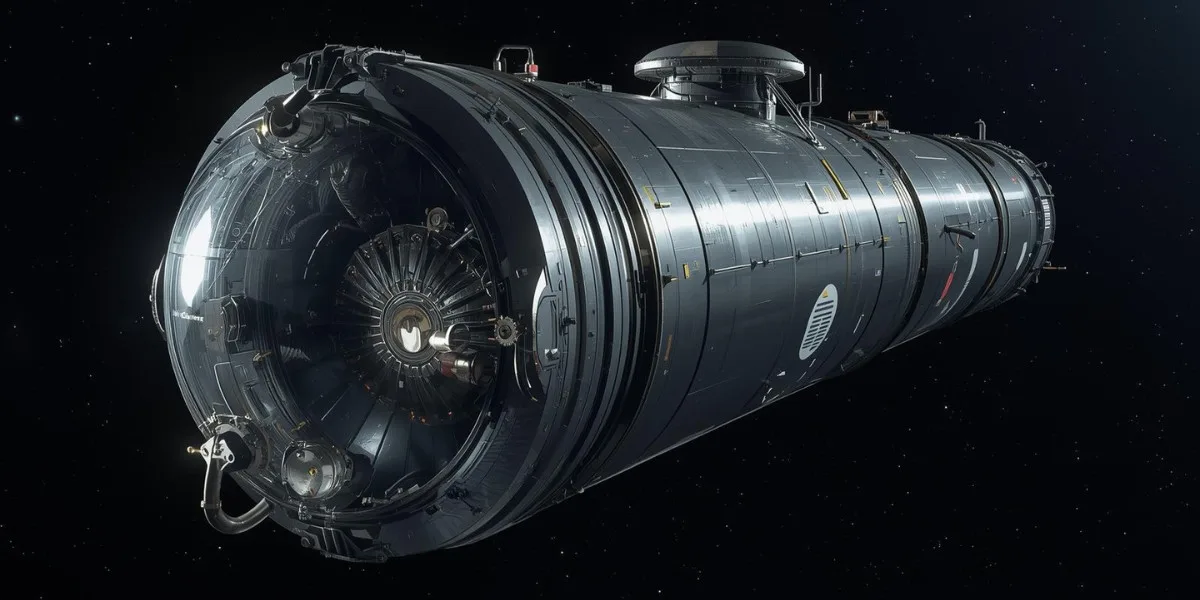

Filament Winding Resin Application enables lightweight, high-strength composite structures for industrial, aerospace, and infrastructure and many more uses.

Packaging must resist moisture, heat, and chemicals. Therefore, manufacturers rely on Protective External Can Coating Resins to ensure durability and safety.

Discover how Vinyl Ester Resin is transforming the composite industry with superior strength, corrosion resistance, and production efficiency.

Discover how UV Curable Resin improves productivity and delivers superior surface finish in modern coating applications.

Discover how Novolac Vinyl Ester Resin delivers unmatched corrosion resistance and durability in severe industrial environments. Learn its benefits, applications, and performance advantages.

Discover how SMC resin applications are transforming lightweight structural components across industries. Learn benefits, uses, and future potential. Read now.