Among these materials, pultrusion resin has gained significant attention. It delivers excellent mechanical strength, electrical insulation, and thermal stability; three qualities essential for safe and efficient power distribution.

Author Archives: CREST

Explore how fire retardant gelcoats enhance safety, durability, and compliance in composite parts used across transportation, marine, construction, and industrial applications.

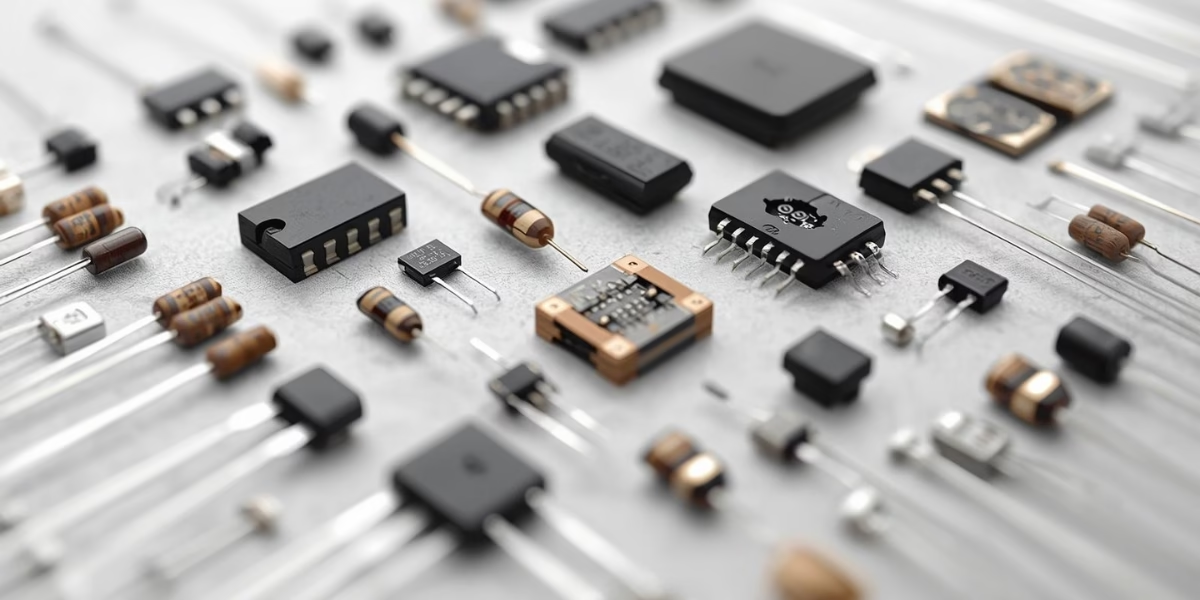

Electrical goods have become an essential part of both home and office spaces. Every switch, socket, or appliance must be safe, reliable, and long-lasting. Therefore, materials used in electrical manufacturing play a critical role in performance. One such material that often goes unnoticed, but delivers exceptional results, is DMC resin. DMC resin, or Dough Moulding […]

Lightweight engineering has become one of the biggest priorities in today’s mobility and energy sectors. With stricter emission norms and rising fuel costs, manufacturers are searching for materials that provide both strength and efficiency. As a result, filament winding resin has become a popular choice in the development of composite drive shafts and advanced high-pressure […]

Learn how Fire Retardant Resin enhances flame safety in FRP tanks, pipes, and equipment used in chemical processing environments.

Discover how Vinyl Ester Resin protects chemical processing equipment from corrosion and boosts long-term reliability. Learn why this advanced resin is becoming an industry favourite.

Discover the key advantages of using fire-retardant resins from improved safety and durability to better compliance and product reliability. Learn why industries trust them for long-lasting performance.

Discover how Fire Retardant Gelcoats protect critical surfaces in transportation, aerospace, and construction. Learn about their real-world applications, durability, and fire safety advantages.

Discover how DMC Resin powers lightweight, durable, and heat-resistant auto components for electric and conventional vehicles. Learn why it’s driving the next generation of automotive innovation.

Discover how Filament Winding Resin delivers unmatched strength, corrosion resistance, and longevity for modern water and wastewater pipeline systems.